Mesh bags are widely used in industries such as agriculture, food packaging, retail, and manufacturing. In agriculture, mesh bags are commonly used for packaging fruits, vegetables, and other produce, allowing air circulation to keep the contents fresh. In retail settings, mesh bags are popular for displaying products like toys, cosmetics, and clothing accessories, offering a visually appealing presentation while allowing customers to see the contents clearly.

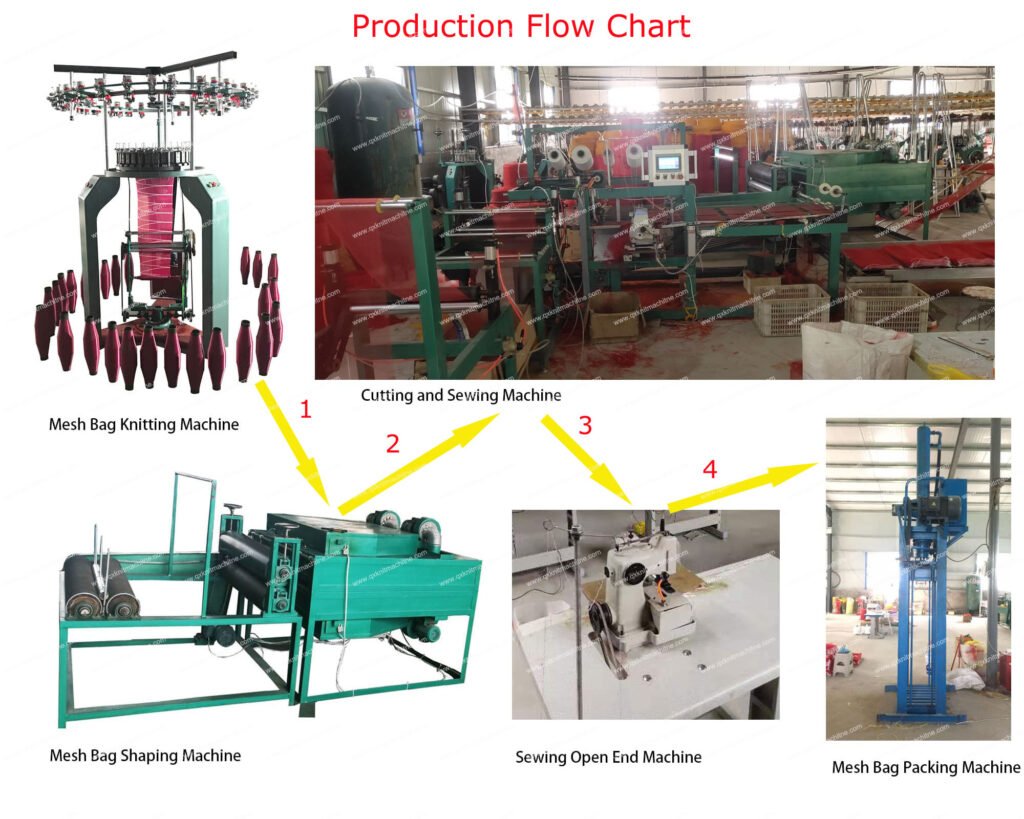

If you are a mesh bag producer looking to optimize your production process, the number of machines you need will depend on various factors such as production volume, desired bag specifications, and available resources. However, to ensure efficient and streamlined manufacturing, a basic setup typically involves the following essential machines:

1, Mesh Bag Knitting Machine:

The foundation of mesh bag production, a mesh bag knitting machine, is operated by computer, applies round HDPE or LDPE monofilament yarn to produce tubular mesh bag. This machine should be selected based on the desired mesh size, material type, and production capacity to meet your specific requirements.

2, Shaping Machine:

After knitting, shaping machines help in shaping the fabric to achieve the desired dimensions and structure of the bags. These machines ensure uniformity and consistency in the final product.

3, Cutting Machine:

To transform the cut mesh into actual bags, a cutting machine is essential. This machine stitches the edges together, forming sturdy seams that can withstand the weight of the produce while ensuring the integrity of the bag.

4, Sewing Machine:

Sewing machines are used for top strawing, where the top of the bag is reinforced to accommodate a drawstring or closure mechanism.

5, Packaging Machine:

Once the bags are sewn, a packaging machine is needed to efficiently pack them for distribution. Depending on your preferred packaging format (e.g., bundles, boxes), various types of packaging machines, such as bagging machines or sealing machines, can be utilized to streamline this process.

Optional Machines:

Printing Machine:

If branding or labeling your mesh bags is part of your production process, a printing machine may be necessary. This machine allows you to apply logos, product information, or other graphics onto the bags, enhancing their visual appeal and marketability.

By investing in the right combination of machinery and technology, mesh bag producers can optimize their production processes, improve efficiency, and meet the demands of their customers effectively. Additionally, regularly assessing and updating your equipment to incorporate advancements in technology can help you stay competitive in the market and ensure the continued success of your business.

Below Picture show all the machines you need and the flowchart for produce a mesh bag.